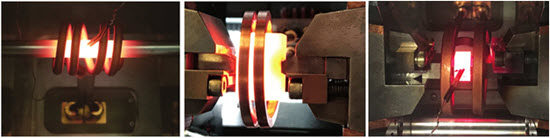

Induction Heating Now Available on Gleeble Systems

Gleeble systems have historically relied on direct resistance to provide extremely fast, uniform and responsive heating. While this method offers considerable advantages over other heating techniques, there are cases where induction heating is preferred. DSI has introduced the Gleeble Induction Heating System (IHS) which provides an alternative heating method to increase testing flexibility.

The Gleeble IHS is fully integrated with the Gleeble and allows the user to select either induction or resistance heating for each test. Induction heating can be useful for heating bi-metallic, non-symmetrical and unique specimens and can be used in tensile testing, heat treating applications and compression tests including uni-axial (flow stress) and plane strain simulations.

An interesting application for induction heating is the unique ability to use non-conductive anvils and lubricants. This allows researchers to minimize thermal gradients across a specimen by minimizing heat loss through the anvils as well as reduce friction between the anvil and the specimen. These features are particularly beneficial for flow stress testing by reducing the barreling effect.

As always, the full capability of the traditional high-speed Gleeble direct resistance heating system is still maintained, allowing heating rates up to 10,000ºC/second when using direct resistance heating. The two heating systems are both integrated to work on the Gleeble and software can be used to select which heating system is used in each test.

To learn more about the Gleeble Induction Heating system, please click here to download a brief information sheet or reach out to the Gleeble team to discuss your application. (info@Gleeble.com)

New Gleeble Catalog Available

New Gleeble Catalog Available

Our team has recently published an updated Gleeble catalog of systems, parts and accessories. The catalog is a great resource to learn more about equipment that will enhance your research and is available electronically as a pdf download. (Click here to download the catalog)

If you prefer, you can request a printed catalog by visiting the Gleeble website and filling out the Catalog request form located here.

As always, DSI staff is available to answer any questions you may have about accessory compatibility, enhancements, calibrations or system operation. Please contact our team at Parts@Gleeble.com for guidance.

Impact of Tariffs

There has been a lot of news recently about tariffs and escalating tensions between the United States and numerous trade partners. In particular, the steel and aluminum industries have been highlighted as key areas of focus. As a US-based manufacturer and exporter that supports the steel and aluminum industries, DSI is closely monitoring these developments.

There has been a lot of news recently about tariffs and escalating tensions between the United States and numerous trade partners. In particular, the steel and aluminum industries have been highlighted as key areas of focus. As a US-based manufacturer and exporter that supports the steel and aluminum industries, DSI is closely monitoring these developments.

While tariffs and trade tensions may cast a short-term cloud over many industries, the pressure to innovate new, lighter, stronger and more efficient materials is not going away. As external factors place more pressure on manufacturers, those organizations that are able to innovate and gain efficiencies will flourish. Our team is proud of the role that Gleeble equipment plays in this process. Now, more than ever, Gleeble systems are critical to drive innovation and provide our users with a competitive advantage.

In addition to tariffs; currency fluctuations, economic trends and increased manufacturing costs are impacting the industries we serve. While it is unclear how these global factors may impact each of our customers, our team is committed to working with each of you to address your individual concerns and offer creative solutions to help researchers acquire the Gleeble equipment necessary to achieve their research goals.

If you are considering a Gleeble purchase or an enhancement to a current system, please reach out to our team and let us know how we can help you and your organization navigate the process.

Gleeble User Meetings

The Gleeble community recently gathered at two user meetings, one in China and one in Germany. We would like to thank the organizations that hosted these meetings and the individuals that made the events such a success. User meetings offer a unique opportunity for researchers to come together to network, present findings, and learn from fellow "Gleeblers". User meetings are tailored for users of all levels, with content that is useful for those that have never touched a Gleeble before, as well as for seasoned Gleeble veterans.

If you have not been to a user meeting, we hope you will be able to join us for a future gathering. The next meeting will be held in India later this month on October 12-13, 2018 at IIT Roorkee. If you are interested in attending, please contact the DSI India team.

There are several user meetings each year. Check the Gleeble website for announcements for future events.

**********************************

Xi'an, China: August, 2018

One of the largest user meetings ever, the 2018 China Users Meeting held in Xi'an China was a resounding success. The meeting was organized and hosted by several leading research organizations. We would like to thank the staffs at 西北有色金属研究院 (Northwest Non-ferrous Research Institute), 西安交通大学 (Xi’an Jiaotong University), 西北工业大学 (Northwest Polytechnical University), and 中国石油天然气集团公司管材研究所 (China National Petroleum Corporation Xi’an Pipe Research Institute) for welcoming the Gleeble community to Xi'an.

Attended by researchers from some of the largest metals producers in the world, the community enjoyed presenting research and success stories as well as attending training sessions and learning about Gleeble system maintenance and operation enhancements. There were impressive examples of Gleeble usage, including the system at the Chinese Academy of Sciences' Institute for Metal Research in Shenyang which was installed in 1983 and is still in operation today. There were also numerous examples of Gleebles driving innovation that resulted in significant returns on investment and accelerated R&D cycles.

Erlangen, Germany: September, 2018

Over 60 researchers converged at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) in Erlangen, Germany at the LFT Institute for two days filled with Gleeble presentations and networking. We are grateful to the staff at FAU for hosting the group and for the presenters and participants for making the event valuable and fun. Based on the success of the meeting, several organizations have volunteered to host future meetings in 2019 and beyond. Check the Gleeble website for future announcements about future gatherings.

Mahesh K.Kumawat, Md Zafir Alam, Atul Kumar, K.Gopinath, Sabyasachi Saha, Vajinder Singh, V.Srinivas, D.K.Das

Defence Metallurgical Research Laboratory, Hyderabad 500 058, India

Abstract: Fe-Cr-Si coated Nb-alloy C103 is a strategic material for advanced structural high temperature applications in hyperplanes. The coating provides oxidation resistance and is indispensable for high-temperature use of the C103 alloy. However, the coating is constituted of brittle intermetallic silicide phases, which can affect the tensile properties of the substrate adversely. The present paper examines the effect of coating on the tensile properties of C103 alloy. The tensile properties have been evaluated at various temperatures up to 1500 °C using the Gleeble test facility. For low test temperatures up to 900 °C, the coating exhibited extensive brittle cracking and spallation, which caused reduction in the YS and UTS of the substrate alloy by 10–20%. On the other hand, the coating showed ductile deformation and it did not affect the strength of the alloy at temperatures of 1100 °C and above. At all test temperatures, the substrate alloy was ductile enough to resist the penetration of the coating cracks into the substrate, and the ductility of the alloy was not affected significantly by the application of the coating. The fracture behavior in the coating at various temperatures and implications on the tensile behavior of the substrate alloy are discussed.

Optimizing Annealing Parameters with Gleeble simulation for Cold Rolled Continuous Annealed Dual Phase Steel Sheet

Rajan Kr Singh, Madhawan Chandrawanshi, R Sudharshan, Devasish Mishra, Ashish Chandra (JSW Steel Ltd)

Abstract: Cold rolled dual phase steel sheet with 590 MPa UTS level (DP590) were processed in continuous annealing line and results were compared with Gleeble simulated results. To achieve the typical characteristics like fatigue, hole expansion, phosphatability and good aesthetics; it requires design of compositions and suitable microstructures by controlling the processing parameters of rolling, heating and cooling processes. Thus, the effect of Different annealing parameters for DP590 steel was studied at Gleeble-3800 thermo mechanical simulator and continuous annealing line (CAL). Microstructure and mechanical properties are compared with different annealing cycles. Tensile strength has significant improvement with decrease in rapid cooling temperature were observed in simulated samples and in CAL inline coils, whereas decrease in tensile strength were observed due to decomposition of martensite at higher rapid cooling as well as overaging temperatures. It is also concluded that increasing annealing temperature beyond Ac3 does not increase the martensite fraction as well as tensile strength in continuous annealed steel. In addition, Influence of higher Mn weight% on phosphate chemical conversion coating treatment was investigated. Hole expansion results of DP590 steel for different C weight% were also compared.

Experimental and Theoretical Studies on Formability of 22MnB5 at Elevated Temperatures by Gleeble Simulator

Rong Shean Lee, Ta Wei Chiena – (Department of Mechanical Engineering, National Cheng Kung University) Yi KaiLin (Iron & Steel R&D Department, China Steel Corporation)

Abstract: This paper, which includes an experimental analysis and theoretical predictions, presents a method to investigate the formability of high strength steel sheet 22MnB5 at elevated temperatures. In this method, two designs for tensile test specimens with laser engraving grids are developed and used to obtain the strain paths of a uniaxial tensile state and the plane strain occurring at elevated temperatures using a Gleeble simulator. On the other hand, a modified Cockcroft criterion that takes strain path into consideration is employed to predict the entire forming limit diagram. A forming limit diagram could be established as a result of using the modified Cockcroft criterion together with the limit strains obtained from the tensile tests based on two novel specimen designs. In this paper, forming limit diagrams at three strain rates and forming limit diagrams at temperatures ranging from 650 oC to 850 oC were established.

Microstructure characterization of Al-cladded Al–Zn–Mg–Cu sheet in different hot deformation conditions

Bin LIAO, Xiao-dong WU, Chang-jian YAN, Zheng LIU, Ling-fei CAO, Guang-jie HUANG, Qing LIU (College of Materials Science and Engineering, Chongqing University, Chongqing, China) Yan-li JI (Suzhou Branch, Chinalco Materials Application Research Institute Co., Ltd., Suzhou,China)

Abstract: Al-cladded Al–Zn–Mg–Cu sheets were compressed up to 70% reduction on a Gleeble–3500 thermo-mechanical simulator with temperatures ranging from 380 to 450 °C at strain rates between 0.1 and 30 s−1. The microstructures of the Al cladding and the Al–Zn–Mg–Cu matrix were characterized by electron back-scattered diffraction (EBSD) and X-ray diffraction (XRD). The microstructure is closely related to the level of recovery and recrystallization, which can be influenced by deformation temperature, deformation pass and deformation rate. The level of recovery and recrystallization are different in the Al cladding and the Al–Zn–Mg–Cu matrix. Higher deformation temperature results in higher degree of recrystallization and coarser grain size. Static recrystallization and recovery can happen during the interval of deformation passes. Higher strain rate leads to finer sub-grains at strain rate below 10 s−1; however, dynamic recovery and recrystallization are limited at strain rate of 30 s−1 due to shorter duration at elevated temperatures.

Effect of Nb micro-alloying on microstructure and properties of thermo-mechanically processed high carbon pearlitic steel

I.Dey, S.Chandra, S.K.Ghosh (Department of Metallurgy & Materials Engineering, Indian Institute of Engineering Science and Technology, Shibpur, Howrah 711 103, India)

R.Saha (Product Development Group, R & D Division, Tata Steel Limited, Jamshedpur 831 007, India)

Abstract: Two C-Mn-Si steels with and without Nb micro-alloying are selected in the present study. Both these high carbon steels have been thermo-mechanically processed using Gleeble 3800 simulator. Optical microscope (OM), scanning electron microscope (SEM), transmission electron microscope (TEM), atomic force microscope (AFM) were utilised for microstructural characterisation. The austenitising temperature was varied from 1150 °C to 1200 °C followed by hot compression and subjected to free cooling to evaluate the influence of austenite grain size on transformed microstructure and mechanical properties. It is evident that higher austenite grain size is obtained for both types of steels subjected to higher austenitising temperature. The refinement of pearlite interlamellar spacing (<0.20 μm) with degenerated morphology as well as finer prior austenite grain size (<40 μm) is found to be more prominent for Nb micro-alloyed sample. The average hardness values of both the steels are higher for the specimens, treated at a higher austenitising temperature which is attributed to finer interlamellar spacing. Finally, the correlation between the evolving microstructure and resulting mechanical properties (hardness and yield strength) has been made.

Connect with DSI on LinkedIn: Many professionals use LinkedIn to build their networks and develop collaborations. Please consider following DSI's company page and joining the LinkedIn Group titled: "Gleeble Thermal Mechanical Simulators". You can do this by using the links below.

| You can "Follow" DSI by clicking here or by logging in to LinkedIn and searching for our company, but please note there are several companies named "Dynamic Systems". Please be sure to follow the company titled "Dynamic Systems Inc (Gleeble)" | |

| Please join the group titled "Gleeble Thermal Mechanical Simulators". Here you can post messages, see what's new in the Gleeble community and connect with other users. |

Dynamic Systems Inc.

323 NY 355 Poestenkill, NY 12140

+1(518) 283-5350 | News@Gleeble.com

©Copyright 2018 Dynamic Systems Inc. All Rights Reserved